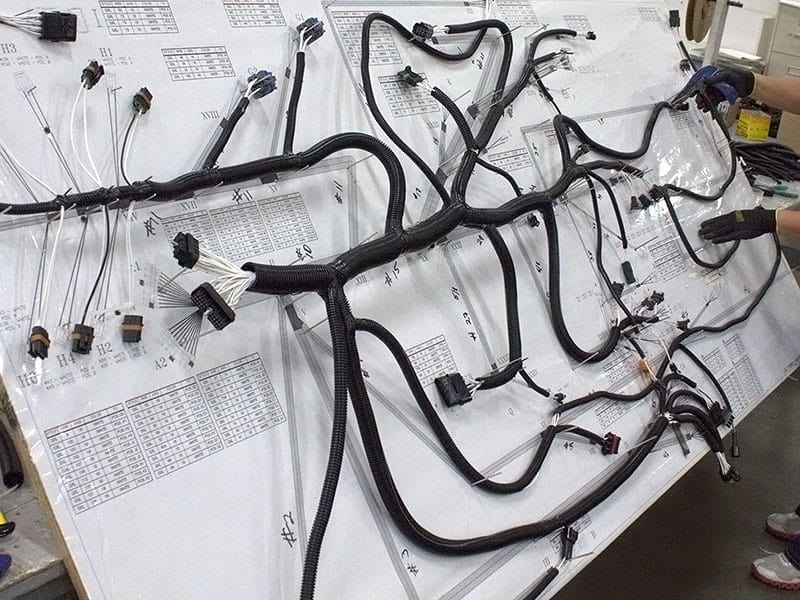

Manufacturing Capabilities

Modern equipment and professional team

Factory Overview

Modern manufacturing facility with advanced equipment from Japan

10,000

m² Factory Area

500+

Employees

50+

Modern Machines

98%

OTD Rate

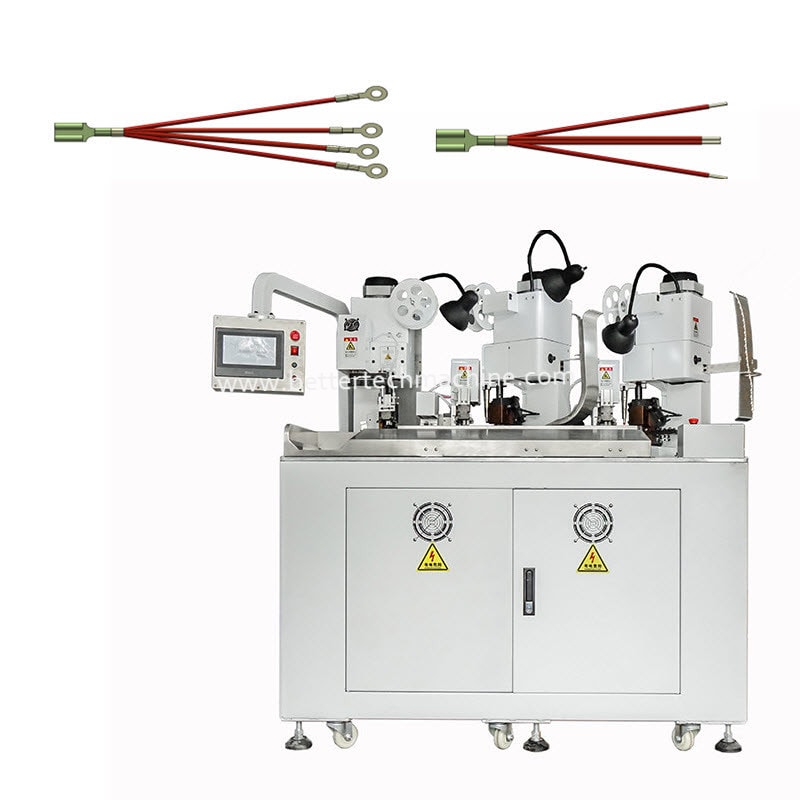

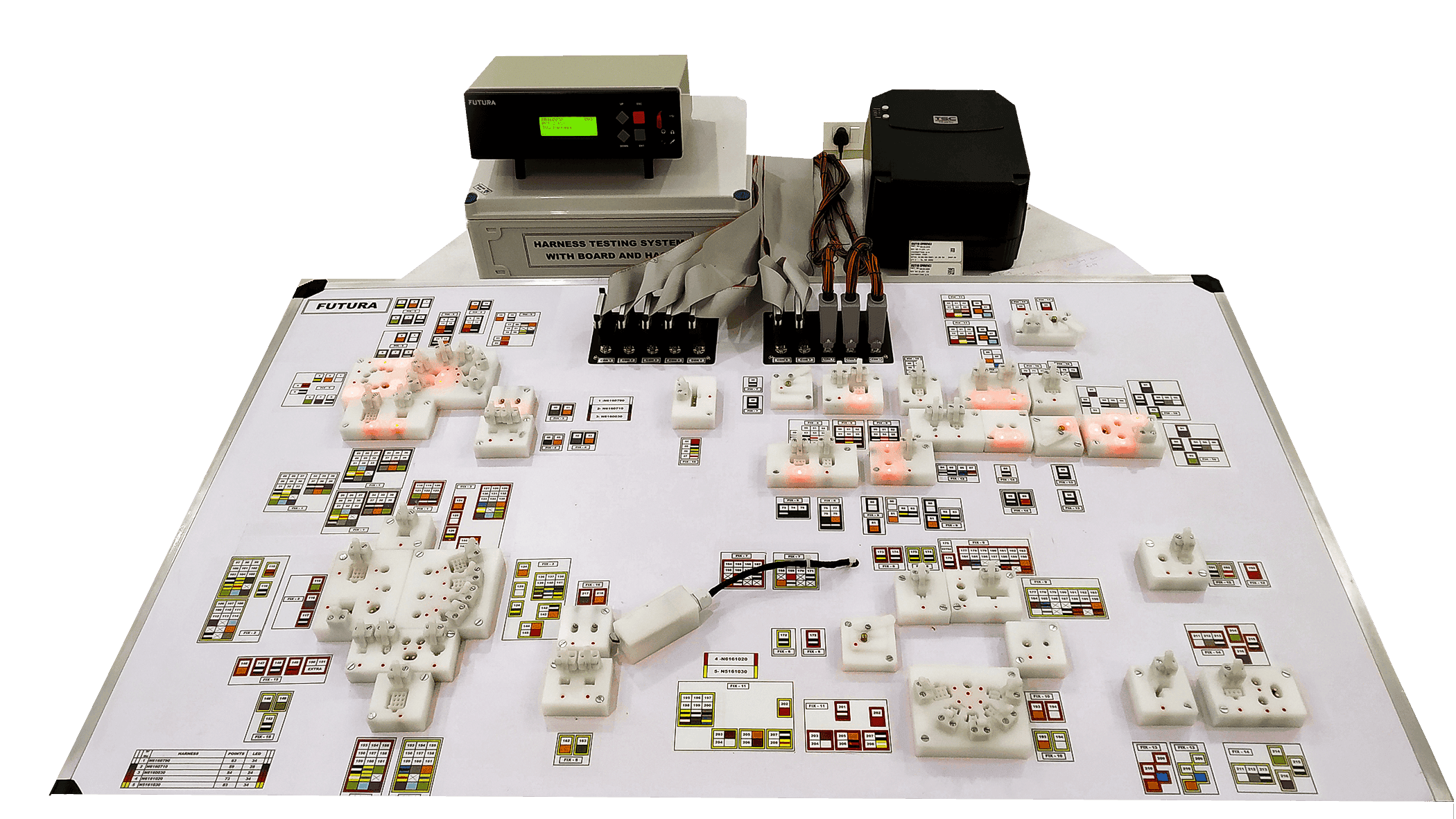

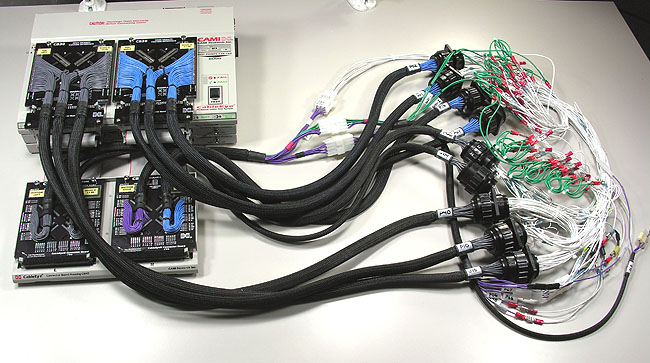

Equipment

Modern machinery system ensuring product quality

Equipment List

Modern machinery system ensuring product quality

Cutting Machines (2 items)

Crimping Machines (3 items)

Testing Equipment (3 items)

Production Capabilities

Diverse production capabilities to meet all requirements

Wire Specifications

- Wire Gauge: AWG 30 - AWG 4

- Length: 10mm - 50m

- Material: Copper, Tinned Copper, Aluminum

- Insulation: PVC, XLPE, Silicone, Teflon

Connector Types

- Automotive: Yazaki, Sumitomo, Delphi

- Industrial: Molex, JST, TE Connectivity

- Custom: Custom Design

- Terminals: Ring, Spade, Quick Connect

Protection Accessories

- Tubing: Corrugated, Braided, Heat Shrink

- Tape: PVC, Cloth, Foam

- Grommet: Rubber, Silicone

- Clips & Ties: Cable Tie, Mounting Clip

Productivity

- Prototype: 1-50 pcs, 3-5 days

- Small Batch: 50-500 pcs

- Mass Production: 1,000-100,000+ pcs/month

- Lead Time: 2-4 weeks